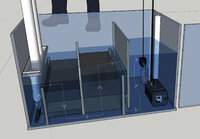

Hi Zak, how is your sump going? I have designed one here :

https://www.ukaps.org/forum/attachments/sump-idea-jpg.112666/ and wonder what your thoughts are on it based on how well yours works? I was trying to think of a good way to dissolve the co2 so this was my solution - are you seeing much co2 evaporation?

Hi,

Very impressive drawing! You go to great levels just to design your sump.

1.

I noticed that you plan to have PPI foam in 3 seperate chambers. - this I personally feel is an overkill.

Your flow might be slowed down dramatically and will be slowed down even further as the foam starts to collect bio film inside them.

Since you're planning to use filter sock, go for 200 micron filter sock. With 100 micron your water will be more clear but the downside is, the 100 micron filter sock will get clogged up fast. If you can spare the time and effort to change the filter sock every 2-3 days, 100 micron will be a good match. I'm using 200 micron as I can't spare the time for now to do the changes.

I'm even planning to use 300 micron sock when I'm out of town for more than 1 week. We don't want a clogged up filter sock and have dirty water overflowing in to the other compartments.

If in case any waste / leave matter manages to escape the filter sock (due to overflow from the clogged up filter sock), you can place some sponge blocks ( marked in yellow) in the chamber right after the filter sock. But even then it can half of what you've planned now.

2.

In the next chamber, use filter floss instead of foam. As filter floss is cheaper, you can simply toss them away when they become dirty and replace with a fresh and clean floss.

3. Have purigen and carbon as labeled in the graph below as they these need periodic replacement. Have the bio media at the bottom as they will hardly be touched. If you place the purigen/carbon, the bio media will have to be taken out everytime and this can be a messy and wet affair.

🙂

4.

Remove the steps in the next chamber as they can potentially slow down flow. Furthermore they can be be a hassle to clean. It will be difficult to reach the bottom of that chamber if in case you need to clean that area too.

5.

You certainly don't want Co2 diffusion at the bottom of the chamber as indicated in your drawing.

First, when it comes to replacement or cleaning of the ceramic co2 diffuser, it's can be troublesome, messy and very wet. You will have to take out everything that chamber. Running a sump is supposed to make things easier not more complicated and troublesome for us.

Have the diffuser next to the return pump where the water will be the cleanest. It'll be easier to troubleshoot co2 related issued ( co2 hose coming off loose / clogged up ceramic etc...). Visually monitoring of co2 diffusion will be easier.

6.

Make the baffle marked with yellow arrow lower than baffle marked A by 1 to 1.5 inch for smoother flow.

7.

Have at least 2 inch gap between baffles as marked. Easier to clean the bottom. More smoother flow.

8.

Make sure that all the baffles have at least 1 inch gap from the top of the tank. In a worst case scenario, if for some reason all the chambers do get blocked, water should still be able to flow to the last chamber where the return pump is. The added space would also be able to take the return water if water back flows from the return pipe into the sump. This might never happen but you never know. It's like insurance.

9.

If you haven't bought the return pump, go for a DC pump rather than a AC pump.

Get a DC pump that is slightly overrated ( example: if your current need is 1000 lph, go for higher output). DC pumps can be dialed back (better flow control) and the new models come with slow start ( not available with AC pumps).

With spare flow capacity from the pump available to you, you can upgrade to a Co2 reactor when the time comes, have more flow in your tank when you change your scape (less dead spot areas in tank)...the list goes on.

I'm sure the other members can chip in too.

BTW, what kind of overflow system are you planning...Herbie style...etc...?

PS. You can even remove the plastic bio balls and add more bio-media....just a thought. What do you think?

Keep us updated.

Take care

🙂