Zeus PLC Build (summary) will add links when I have time

I was after a unit that would turn lights on and off and also dim the Four kessil A160 that I had purchased. The Kessil Lights dimmer function works on an Industry standard of an analog input 0-10V controlling the Lights Intensity and spectrum so I needed two analog outputs in the 0-10V range.

Plus one feature I came up with that I fancied was the

Moonlight Passover phase. Where one kessil would be on its lowest setting at a time for 10-20mins each. Thought it would look great. The issue with this is that the Kessil 160 pass on their analog 0-10V input only when the power is on the Kessil light. I could leave the power on and just use eight different 0-10V inputs but that would of needed four

Siemens LOGO! 8 AM 2 AQ at £100 each. So I decided to wire the analog inputs in parral to the Kessils and then have the PSU for each kessil on a timmer. So Four Outputs need for kessils.

The T5 Ballast I have has two plugs on it one for tubes 3&4 and another for tubes 1,2,5 &6. So two outputs needed there.

One for pH controller power, Plus two for the Twin solenoids I have for duel CO2 injections, one for booster period other for maintaining pH drop so three for CO2 control.

One for Filter

One for twin heaters

One for Ehiem 3000+ which is on an independent loop to maintain good flow and for CO2 booster injection.

One for Air pump

Three for auto dosser - Macros. Micros and LCO2

One for fish feeder

So 17 outputs needed. The base unit has Four outputs and expansion modules come in four or eights.

So went for 20. Auto top up was an option at the time, but with hooded Rimmed tank water loss isn’t an issue

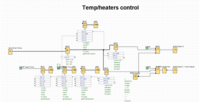

I was after controlling when the heaters came on and off also so two choices with the PLC

Siemens LOGO! AM2 RTD plus PT100 – large linear temp range very accurate but costly.

Rugged Vinyl Tipped Thermistor Sensor which with a bit a soldering resistor and capacitor could give a 0-10V input to the PLC base unit and measure the temp in a non linear way is a less accurate way- but accurate enough IMO.

So a choose the later.

So the PLC just monitors the volts bit of programing set your on off values and heaters on and off Via PLC, just set the heaters at slightly higher temp and failsafe.

Provisional design ATM

Plus I Have added a slightly lower temp for night time, plus heaters off during initial CO2 booster period.

I have yet to Fit the Sensor as it was last on my list, ordering Friday.

So orderd ( well messed up order a few times but got therein the end)

LOGO! 12/24 RCEo, LOGO! Power 24 V, 1.3 A, LOGO! TDE

LOGO8 DM16 24 R (x2)

AM2 AQ expansion module, voltage supply: 24V DC, 2 AO (Analogue Outputs), 0-10V, 0/4-20mA.

The total width off the PLC was 305mm. after much looking around went for TK PS Plastic Enclosure, IP66, 360 x 254 x 111mm From RS with 220 x 331 x 2.5mm Mounting Plate for use with TK Enclosure

But it was still going to be tight. And wire manament wasn’t going to be easy I bigger Enclosure would off been better for wiring but too big. So leap of faith required.

I wasn’t going to be able to wire it like I had thought so raised the 35mm Din rails and ran wire under Din rail

so

and just fit

Little on tight for room for switches

20 socket output MDF

About this point I decided to put the PLC enclosure on the side wall off cabinet.

20 live wires to get from enclosure to outlets plus neutrals and earths. So decided on ring for neutrals and earth then separate live feeds.

Used the Fluval FX6 piping and a Gland

Then found out the entry point for the wire to the PLC enclosure wasnt going to work

wired up my monmentory push switches off ebay and some very nice locking swicthes of Ian he had left over

Raised the Lower DIN rail on Left hand side so wires to outlets could be passed in.

The enclosure had to be fitted in the cabinet before the DIN rails

Was a little tight for space but got it wired up. Uploaded my software and was working

To date the legend for the inputs and outputs is

This took quite soon time to decide and work out, but its working great but not finished.

This took quite soon time to decide and work out, but its working great but not finished.

Ian_m has been a massive help with daily multiple PM at times going back and forth since October 2016. I cant thank Ian enough for his MASSIVE help and patience

( reposted as images not working and no edit on post)

but we dont need that degree of accuracy for a fish tank, after all who has their tank at 26.347 degrees? tenth of a degree is plenty IMO

but we dont need that degree of accuracy for a fish tank, after all who has their tank at 26.347 degrees? tenth of a degree is plenty IMO