zozo

Member

Don't have to say, but do it anyway, i'm a sump filter fan.. And i notice people tend to think it's difficult and expensive and to large and all. But nothing is further from the truth, most people having a sump likely will agree and confirm. Now i was thinking of a nano sump for a nano thank..  And thought lets create minimaly distracting and a small, cheap as possible overflow anybody can make and see how it performs.. I was thinking at least 250 l/h performance so you could reach a 10x turnover with a 25 litre tank. And create a sump out of a 10 litre bucket if yuo like..

And thought lets create minimaly distracting and a small, cheap as possible overflow anybody can make and see how it performs.. I was thinking at least 250 l/h performance so you could reach a 10x turnover with a 25 litre tank. And create a sump out of a 10 litre bucket if yuo like..

I took the principle of the standard overflow box available in the LFS or for us Europeans via Ebay since most of them are made in USA, sump country No.1. Smallest available 800 gallon capacity. $10 per 100 gallon.. It's not the first time this is build, seen it before on utube, all tho the versions i've seen where exeptionaly crude and still a bulky build. I sized it down even further and neated it a bit up..

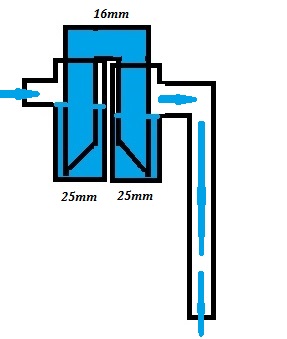

This is the crude diagram in idea of what is readily available for us in any hardware store. Standard PVC components.

This is the actual overflow as i build.

Didn't have any knees available at the time so i did bend the 16mm pvc tube in a U tube. For the rest i think i don't have to explain all the used components, I think the pic speaks for itself. If not please ask..

the only thing i used differtly instead of a T in the tank side. It is 25mm PVC tube and a filter inlet basket of a cheap SUNSUN filter in/outlet set. I was only using the outlet spray bar in my aquariums. So i have a few inlets to play around with. Funny is these baskets are excactly 25mm and fit snugly over the tube. Did cut a hole in the top, sanded it a bit larger to make it snugly fit a 16mm pvc tube and it works like a charme.. It can slide up and down as well to change the drainage in the tank. And it saved me a T and a reducer.

The left hand side is the in tank overflow, this actualy doesn't need to be glued if it fits snugly, it will be submersed all the time anyway.. The right hand side is the outside tank water lock. The reducer on top of the T obviously has a retainer bumber inside, this needs to be sanded out so the u tube can be sunk all the way down into the water lock.. You only need to glue the reducer into the T. The tube into the T and the cap on the tube. The water never reaches the top and if the U tube aint glued it can change possition 180°. And makes it possible to take all apart for cleaning. And this small size you don't need to prime it.. Dip in a bucket with water take it out and it's ready to run. Put a cupling at the outlet end to go on to the sump..

Test run! Approximately it performed better than expected.. According my stop watch calculations it drains about 300 l/h. I created a split drain pipe bellow my 100 litre low tech tank, so i could sufice with 2 of these small ones to reach my 6 x turn over.

I created a split drain pipe bellow my 100 litre low tech tank, so i could sufice with 2 of these small ones to reach my 6 x turn over.

So obviously it works pretty well, why not?.. It's a super mini overflow box.. And you can make it any size you like, go bigger if you want it in a bigger tank.. I guess can't get it much cheaper than this..

So obviously it works pretty well, why not?.. It's a super mini overflow box.. And you can make it any size you like, go bigger if you want it in a bigger tank.. I guess can't get it much cheaper than this..

Have fun.

I took the principle of the standard overflow box available in the LFS or for us Europeans via Ebay since most of them are made in USA, sump country No.1. Smallest available 800 gallon capacity. $10 per 100 gallon.. It's not the first time this is build, seen it before on utube, all tho the versions i've seen where exeptionaly crude and still a bulky build. I sized it down even further and neated it a bit up..

This is the crude diagram in idea of what is readily available for us in any hardware store. Standard PVC components.

This is the actual overflow as i build.

Didn't have any knees available at the time so i did bend the 16mm pvc tube in a U tube. For the rest i think i don't have to explain all the used components, I think the pic speaks for itself. If not please ask..

the only thing i used differtly instead of a T in the tank side. It is 25mm PVC tube and a filter inlet basket of a cheap SUNSUN filter in/outlet set. I was only using the outlet spray bar in my aquariums. So i have a few inlets to play around with. Funny is these baskets are excactly 25mm and fit snugly over the tube. Did cut a hole in the top, sanded it a bit larger to make it snugly fit a 16mm pvc tube and it works like a charme.. It can slide up and down as well to change the drainage in the tank. And it saved me a T and a reducer.

The left hand side is the in tank overflow, this actualy doesn't need to be glued if it fits snugly, it will be submersed all the time anyway.. The right hand side is the outside tank water lock. The reducer on top of the T obviously has a retainer bumber inside, this needs to be sanded out so the u tube can be sunk all the way down into the water lock.. You only need to glue the reducer into the T. The tube into the T and the cap on the tube. The water never reaches the top and if the U tube aint glued it can change possition 180°. And makes it possible to take all apart for cleaning. And this small size you don't need to prime it.. Dip in a bucket with water take it out and it's ready to run. Put a cupling at the outlet end to go on to the sump..

Test run! Approximately it performed better than expected.. According my stop watch calculations it drains about 300 l/h.

Have fun.

Last edited: