2

22802

Guest

Thread starter

Inspired by this great project (thank you @Unexpected 🙏 ) some new insights ...

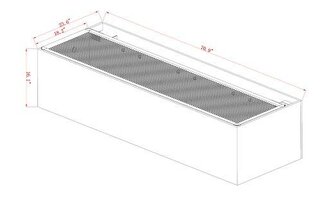

We may want to reduce the capacity of our horizontal reactor, so that even when something goes wrong (regulator, pH/CO2 controller failure) we are not at risk gassing our lifestock. This is a key benefit of CO2 Spray Bar, but it appears this can easily be replicated on the Horizontal CO2 Reactor.

Raise the end of the reactor a bit, so that CO2 starts purging through the exit. Assume, we target a 1.0 pH drop for the tank, we may then raise the reactor exit to the point where the purging of CO2 will make sure our pH can never drop more than 1.1 - limited by the reactors capacity.

No need to worry anymore about injecting too much CO2, points of failure, as we have now made the reactor inherently safe 🙂

I have tested CO2 Spray Bar in overflow mode , which has the benefit of inherent safety but also that we do not longer depend on the accuracy and stability of our CO2 regulator. We may want to test in the future if same can be achieved with a horizontal generator, slightly adjusted from the horizontal level.

We may want to reduce the capacity of our horizontal reactor, so that even when something goes wrong (regulator, pH/CO2 controller failure) we are not at risk gassing our lifestock. This is a key benefit of CO2 Spray Bar, but it appears this can easily be replicated on the Horizontal CO2 Reactor.

Raise the end of the reactor a bit, so that CO2 starts purging through the exit. Assume, we target a 1.0 pH drop for the tank, we may then raise the reactor exit to the point where the purging of CO2 will make sure our pH can never drop more than 1.1 - limited by the reactors capacity.

No need to worry anymore about injecting too much CO2, points of failure, as we have now made the reactor inherently safe 🙂

I have tested CO2 Spray Bar in overflow mode , which has the benefit of inherent safety but also that we do not longer depend on the accuracy and stability of our CO2 regulator. We may want to test in the future if same can be achieved with a horizontal generator, slightly adjusted from the horizontal level.