SingAlongWithTsing

New Member

Equipment List for the 180

January 2023

All the 2x4s (actual dimensions 1.5" x 3.5") we're ran through a tablesaw to cut off the rounded edges (bringing it down to 1.5" x 3") just to make things easier to fit.

Yeah I know I have a corner clamp but it cracked lol.

The rabbet cuts / detail will come into play later when the stand gets a final coat of BEHR Limousine Leather MQ5-05.

Cut out slots in the access boxes for the optional knitting mesh. The knitting mesh is just to block bugs from getting in to whichever box I'm not using

March 2023

100+ hrs total so far in terms of milling, sanding, cutting, and assembling. not sure how much went to painting cuz my dad volunteered for that lol

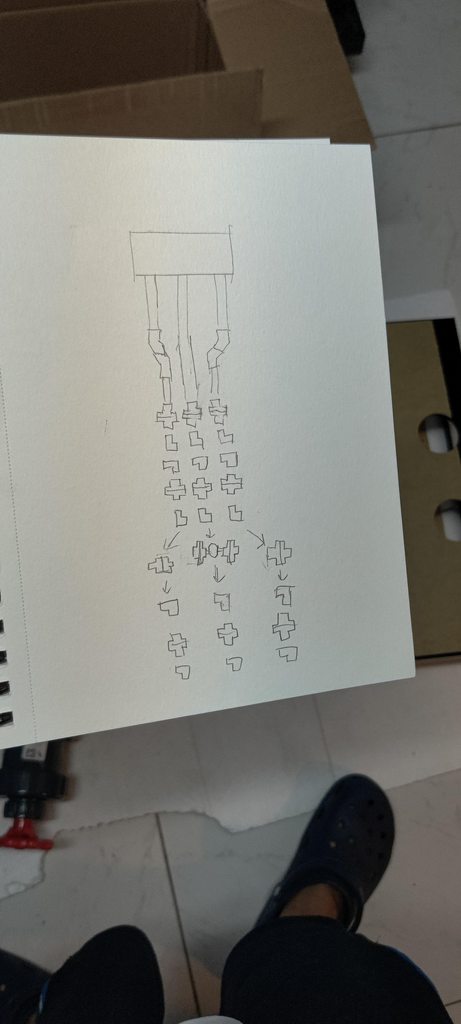

pre-planning the drains and yeah i know the box is reversed lol

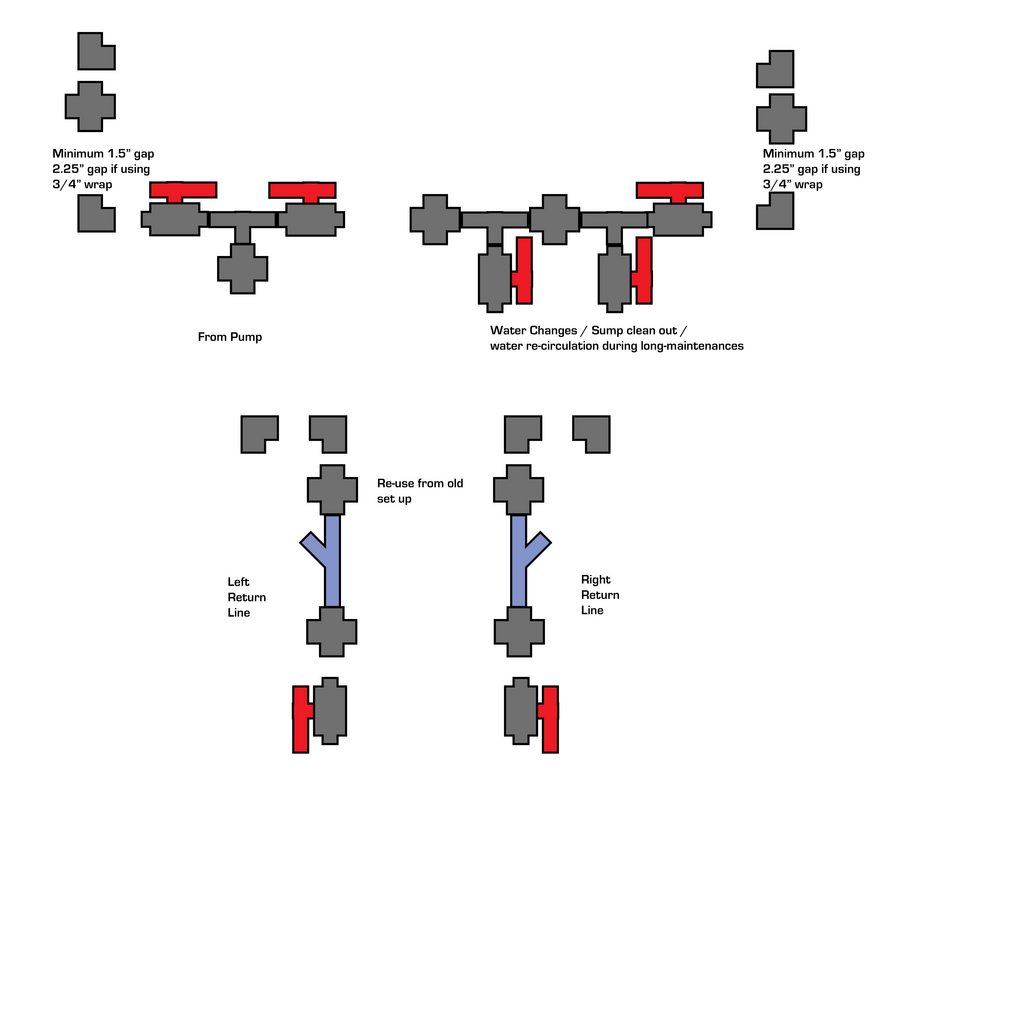

Probably just gonna re-use a bunch of the old return plumbing from the 125 and order replacement slip fittings for the cepex valves

- Hand me down 180 gallon acrylic tank with a blue background from my dad.

- Abandoned 60 gallon acrylic tank from my uncle. Will be welding acrylic baffles and turning it into a sump.

- ABS Black background, will be siliconed with ASI Black Silicone (they said it works on acrylics so it's a gamble)

- My old DIY CO2 Regulator

- My old ozone cone copy cat CO2 Reactors

- 3x Netlea AT6 Pro

- UNS Soil

- My old Jebao EP-M 10000 as the main return pump.

- My old Jebao EP-M 6500 as the CO2 reactor pumps.

January 2023

All the 2x4s (actual dimensions 1.5" x 3.5") we're ran through a tablesaw to cut off the rounded edges (bringing it down to 1.5" x 3") just to make things easier to fit.

Yeah I know I have a corner clamp but it cracked lol.

The rabbet cuts / detail will come into play later when the stand gets a final coat of BEHR Limousine Leather MQ5-05.

Cut out slots in the access boxes for the optional knitting mesh. The knitting mesh is just to block bugs from getting in to whichever box I'm not using

March 2023

100+ hrs total so far in terms of milling, sanding, cutting, and assembling. not sure how much went to painting cuz my dad volunteered for that lol

pre-planning the drains and yeah i know the box is reversed lol

Probably just gonna re-use a bunch of the old return plumbing from the 125 and order replacement slip fittings for the cepex valves

.. I think I remember you from barreport a few years ago?

.. I think I remember you from barreport a few years ago?