The Accidental Aquascaper

Member

The fittings are super tight and I want to check a couple of things before I try to undo something that doesn't undo.

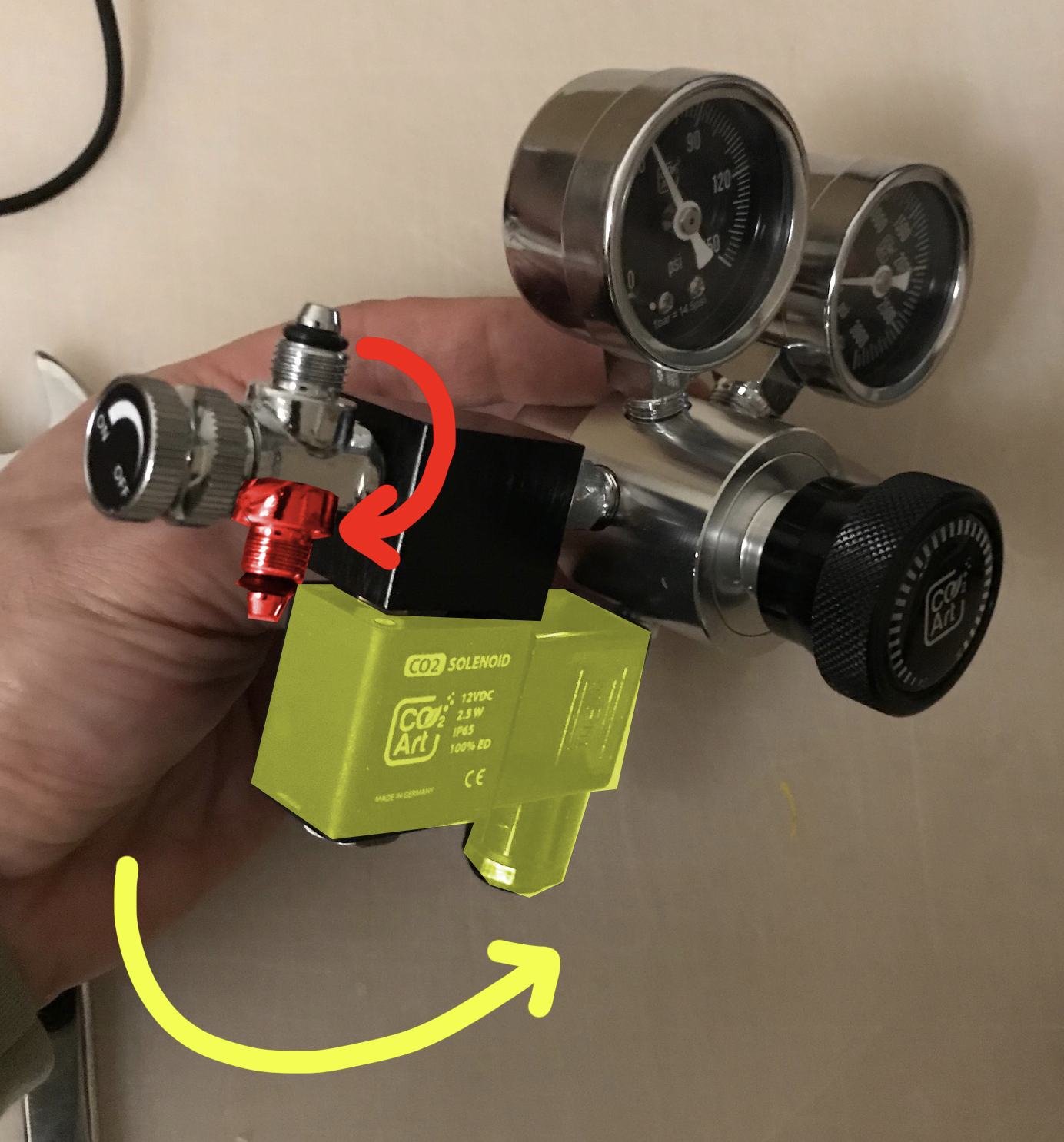

Firstly, does anyone see a problem with rotating the solenoid 180* as per my image in yellow?

I can't see why it would be a problem, as it doesn't get in the way of the cylinder and gives me the option to point the needle valve downwards.

Which brings me to my second question. Is it ok to point the needle valve downwards as per the one in red on image?

I'll be using it with an inline bubble counter and it would make the tubing far neater.

Firstly, does anyone see a problem with rotating the solenoid 180* as per my image in yellow?

I can't see why it would be a problem, as it doesn't get in the way of the cylinder and gives me the option to point the needle valve downwards.

Which brings me to my second question. Is it ok to point the needle valve downwards as per the one in red on image?

I'll be using it with an inline bubble counter and it would make the tubing far neater.