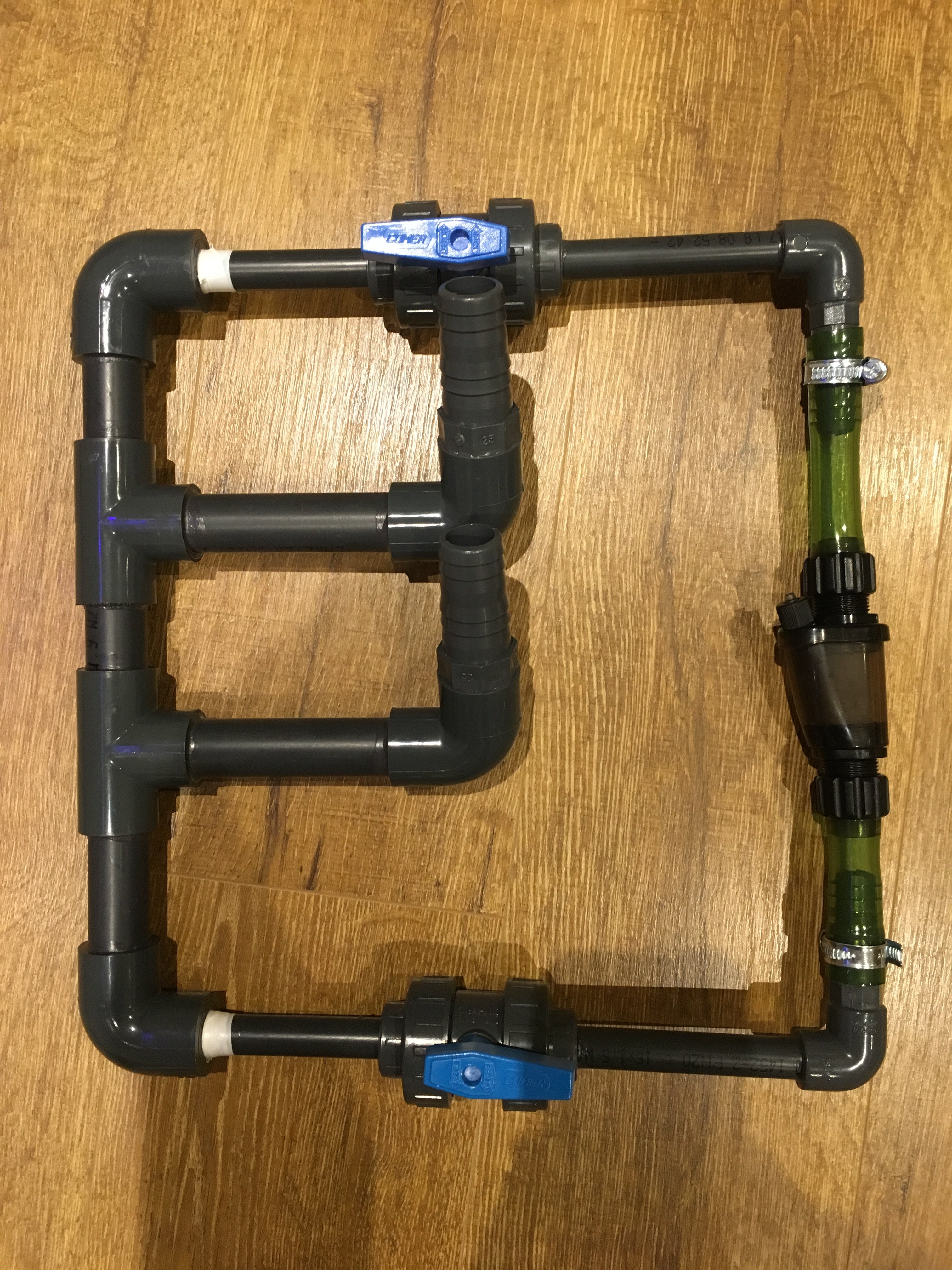

i probably should have posted this before gluing it, but before I start drilling and cutting my cabinet. Will this work?

Needed to create a 16/22mm bypass for a CO2 reactor as my FX4 pipes are 25/32mm and go directly into the tank via an under mount.

The two cut of valves are so that if the reactor needs maintainance or replacing (if it’s rubbish) then I can do this easily. This is going on my outflow. From filter to the bottom connector and then from the top connector, straight into my tank.

The connectors are facing inwards due to the thickness of my cabinet, I wanted this to fit inside to one of the walls.

Needed to create a 16/22mm bypass for a CO2 reactor as my FX4 pipes are 25/32mm and go directly into the tank via an under mount.

The two cut of valves are so that if the reactor needs maintainance or replacing (if it’s rubbish) then I can do this easily. This is going on my outflow. From filter to the bottom connector and then from the top connector, straight into my tank.

The connectors are facing inwards due to the thickness of my cabinet, I wanted this to fit inside to one of the walls.