I guess if it's successful it's a case of then getting the word around. People seem hell bent on inline diffusers but they still leave bubbles so if the reactor was affordable and a success then it should be. That said the aqua medic 1000 doesn't really sell so why is this?Great idea, getting someone who is commercially interested with the right skill set is half the battle. Making a reactor that will be suitable for all tanks is another thing and a range will be needed with the bulk of the market is the smaller tanks also. So the range would have to be suitable for various size piping. May well be worth considering having it made with a bypass as standard, then the flow though the reactor could be adjusted. The big issue IMO is would it sell and how much would it be.

Will be giving it some thought..............

-

You are viewing the forum as a Guest, please login (you can use your Facebook, Twitter, Google or Microsoft account to login) or register using this link: Log in or Sign Up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is an inline reactor really better than an inline diffuser?

- Thread starter Andrew Butler

- Start date

zozo

Member

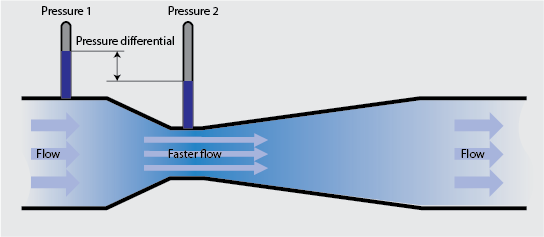

@Edvet He said the magic word..  Venturi! Presure difference.. Google Co2 Venturi systems and you'll find articles from scientific studies in horticulture, proven to be the best way to add CO² to the water.

Venturi! Presure difference.. Google Co2 Venturi systems and you'll find articles from scientific studies in horticulture, proven to be the best way to add CO² to the water.

It actuay is the build up presure in front of the ventury where CO² partialy diffused.. Behind the venturi there is a vortex and a pressure release, the sudden expansion of the water scatters the tiny bubble even more and drives the CO² molecules apart and get sucked into the water column.

So if you are using a reactor that only increases contact time and still releases bubles, because contact time obviously isn't enough relative to amount CO² added, then put a venturi behind the reactor. If necessary enrease pump capacity..

I once heard an interview with the German scaper Jurijs S. He was behind the scenes looking at the techniques used in Amanos Submersed Forest in Portugal and told about it. And he told they used a venturi system to add CO². It intruiged me and i looked it up and it is scientificly proven to be the best way to add CO² even at rather low pressures and flow speed it work beter than any other way.

There is a Topic about Florestas Submersas, where this also is discussed a bit and the links to the scientific papers are in this topic. Can't seem to find it back so quickly.

It works in the excact simple way as the Aeration Venturi on a power head, sucking in air and the vortex created scatters the air and the pressure release makes the bubble even smaller..

I realy wonder why this technique aint used in the smaller aquarium industry for co2. But in theory putting a venturi behind any kind of diffuser should have possitve effect and result in a better diffusing CO². It'll only cost you turn over if pump capacity isn't increased. I haven't realy played with it or tested it myself. I currently have no high tech setup. If i ever do again i certainly will.

This is all i can find back about it it the moment.

https://www.ncbi.nlm.nih.gov/pubmed/22209441

But i know there is an article somewhere with more explaination and diagrams of the test setups in ponds..

It actuay is the build up presure in front of the ventury where CO² partialy diffused.. Behind the venturi there is a vortex and a pressure release, the sudden expansion of the water scatters the tiny bubble even more and drives the CO² molecules apart and get sucked into the water column.

So if you are using a reactor that only increases contact time and still releases bubles, because contact time obviously isn't enough relative to amount CO² added, then put a venturi behind the reactor. If necessary enrease pump capacity..

I once heard an interview with the German scaper Jurijs S. He was behind the scenes looking at the techniques used in Amanos Submersed Forest in Portugal and told about it. And he told they used a venturi system to add CO². It intruiged me and i looked it up and it is scientificly proven to be the best way to add CO² even at rather low pressures and flow speed it work beter than any other way.

There is a Topic about Florestas Submersas, where this also is discussed a bit and the links to the scientific papers are in this topic. Can't seem to find it back so quickly.

It works in the excact simple way as the Aeration Venturi on a power head, sucking in air and the vortex created scatters the air and the pressure release makes the bubble even smaller..

I realy wonder why this technique aint used in the smaller aquarium industry for co2. But in theory putting a venturi behind any kind of diffuser should have possitve effect and result in a better diffusing CO². It'll only cost you turn over if pump capacity isn't increased. I haven't realy played with it or tested it myself. I currently have no high tech setup. If i ever do again i certainly will.

This is all i can find back about it it the moment.

https://www.ncbi.nlm.nih.gov/pubmed/22209441

But i know there is an article somewhere with more explaination and diagrams of the test setups in ponds..

Last edited:

This one?There is a Topic about Florestas Submersas

https://www.ukaps.org/forum/threads...kashi-amano-at-lisbon-oceanarium.36555/page-7

So you are trying to suggest fitting a venturi and injecting the CO2 before the reactor?

The big problem is slowing the flow down if you rely on using your external filter (as I do), would this work if you were to put a bypass on the reactor so not all the flow went through the reactor?

Venturi work as you describe but the principle design is a restriction in the main flow line.

That restriction will cause huge loss of flow, especially when using low wattage pumps.

That would be ok it the reactor had a separate venturi pump.

Vortex designs work better than would ever be required & they do that without loosing too much flow.

I think the tube diameter, the length, the inlet & outlet positioning, & the flow rate would all have an effect on performance.

Building a one off special that can be fine tuned is one thing but making a 'one fits all' will take a lot of experimenting & probably, big company recourses?

My priorities would be a clear vessel, as little reduction in flow as possible, complete with high flow valves, take apart facility & quiet running.

I would rather see one that works than another small unit cheap unit that doesn't! So cost & size would be less important to me.

That restriction will cause huge loss of flow, especially when using low wattage pumps.

That would be ok it the reactor had a separate venturi pump.

Vortex designs work better than would ever be required & they do that without loosing too much flow.

I think the tube diameter, the length, the inlet & outlet positioning, & the flow rate would all have an effect on performance.

Building a one off special that can be fine tuned is one thing but making a 'one fits all' will take a lot of experimenting & probably, big company recourses?

My priorities would be a clear vessel, as little reduction in flow as possible, complete with high flow valves, take apart facility & quiet running.

I would rather see one that works than another small unit cheap unit that doesn't! So cost & size would be less important to me.

zozo

Member

This one?

https://www.ukaps.org/forum/threads...kashi-amano-at-lisbon-oceanarium.36555/page-7

So you are trying to suggest fitting a venturi and injecting the CO2 before the reactor?

The big problem is slowing the flow down if you rely on using your external filter (as I do), would this work if you were to put a bypass on the reactor so not all the flow went through the reactor?

I think it was that one

Think of a Carburator and it's spray nozzle, this sprays gasoline mist into a venturi, when the trottle opens air flow is increases. Than there is a pressure build up in front of the venturi and the gasoline mist is sucked in by the acce;erated air flow into the venturi. Behind it this flow suddenly drops again, results in pressure drop and the air expands again rapidly and this scatters the gasoline droplets into even smaller size so it turns into a gas form before it hits the combustion chamber.

That's the excact same thing fluid dynamic principle. Air mixing gasoline, is fairly the same as water mixing with CO²..

The diffuser (air stone) is your spray nozzle that should be in front or in the venturi.

So the venturi should be behind the diffuser, than the already partialy diffused into small bubbles CO² hits the venturi, it gets more or less compacted together and accelerates in the ventiru, than the tube get bigger again all media leaving the venturi expands again and this kinda rippes apart the CO² molecules into even smaller fragments. Better disolved before it hits the (combustion) tank.

And yes loss of turn over without up grading the pump is inevitable.. A bypass could have possitive effects but i guess you still wil lose some. As the article i linked to states the lowest they tested it on was 4L/m = 240L/h still had a 100% beter result than a airstone only. Than we don't use a regular airstone but a very dense ceramic disk making far smaller bubbles than an airstone.

As said i never realy builded something to see how it works for real.. Currently no high tech tank to play with. Ran out of co2 and didn't feel like buying a new one. The next one i will surely go and experiment with this. For it's a proven theory, need to come up with something to scale it down so it's applicable for smal aqauriums. It works like a charm for the big ones, florestas submersas uses it.

I think it was that onenice find.. But it doesn't contain the paper i refering to.. I know i posted it somewhere, but i lost all my bookmarks due to a HDD crash sans backup.

If i rmember correctly it was via google books, but it's to long ago. The principle is actualy very simple.

Think of a Carburator and it's spray nozzle, this sprays gasoline mist into a venturi, when the trottle opens air flow is increases. Than there is a pressure build up in front of the venturi and the gasoline mist is sucked in by the acce;erated air flow into the venturi. Behind it this flow suddenly drops again, results in pressure drop and the air expands again rapidly and this scatters the gasoline droplets into even smaller size so it turns into a gas form before it hits the combustion chamber.

That's the excact same thing fluid dynamic principle. Air mixing gasoline, is fairly the same as water mixing with CO²..

The diffuser (air stone) is your spray nozzle that should be in front or in the venturi.

So the venturi should be behind the diffuser, than the already partialy diffused into small bubbles CO² hits the venturi, it gets more or less compacted together and accelerates in the ventiru, than the tube get bigger again all media leaving the venturi expands again and this kinda rippes apart the CO² molecules into even smaller fragments. Better disolved before it hits the (combustion) tank.

And yes loss of turn over without up grading the pump is inevitable.. A bypass could have possitive effects but i guess you still wil lose some. As the article i linked to states the lowest they tested it on was 4L/m = 240L/h still had a 100% beter result than a airstone only. Than we don't use a regular airstone but a very dense ceramic disk making far smaller bubbles than an airstone.

As said i never realy builded something to see how it works for real.. Currently no high tech tank to play with. Ran out of co2 and didn't feel like buying a new one. The next one i will surely go and experiment with this. For it's a proven theory, need to come up with something to scale it down so it's applicable for smal aqauriums. It works like a charm for the big ones, florestas submersas uses it.

I'm understanding the principal of how it works but it's just going to restrict the flow too much which isn't what I'm trying to achieve - I just want to create an inline reactor that fully dissolves the CO2 and doesn't restrict flow; no extra pumps, preferably no bypass.

I can't be alone in wanting this can I?

Zeus.

Fertz Meister

If it was constructed with bypass to take the main flow then a pump then CO2 injection then Venturi, it should work with no loss of flow, just the cost of the extra pump and fitting it all in OFC

Needs some R&D, or some decent articles/papers of folk who have done it.

Mine works well, but I think it's the low flow though the reactors with bypass in combo with the pretty wide APS EF so flow very slow in reactors so CO2 gets plenty of time to rise. Think I have a massive CO2 bubble in the reactors.

Since using the reactors been using much more CO2 but also doing a much bigger pH drop. Any more and fish would be dead. If I feed them before CO2 goes of the Harlequins go belly up with the extra CO2 they produce in the excitement of food. They recover without an issue, rest of fish are fine, added another 60 fish on Friday and they all had on issues with a fast pH drop 40mins, yes gasping a bit faster than tanks resident fish, given a few days/weeks sure that will be reduced too. Non at surface except Marble Hackets and Killi Fish but that's where they hang out.

Sent from my Moto G (4) using Tapatalk

Needs some R&D, or some decent articles/papers of folk who have done it.

Mine works well, but I think it's the low flow though the reactors with bypass in combo with the pretty wide APS EF so flow very slow in reactors so CO2 gets plenty of time to rise. Think I have a massive CO2 bubble in the reactors.

Since using the reactors been using much more CO2 but also doing a much bigger pH drop. Any more and fish would be dead. If I feed them before CO2 goes of the Harlequins go belly up with the extra CO2 they produce in the excitement of food. They recover without an issue, rest of fish are fine, added another 60 fish on Friday and they all had on issues with a fast pH drop 40mins, yes gasping a bit faster than tanks resident fish, given a few days/weeks sure that will be reduced too. Non at surface except Marble Hackets and Killi Fish but that's where they hang out.

Sent from my Moto G (4) using Tapatalk

There used to be a great german company making and selling them on ebay, they did cost £80-100 a pop, maybe why they went bust and now all we have left is crappy reactors, I must have tried at least 20 different ones that I could find and they were all crap to be honest, should have purchased one of those german ones back in the day! Even the Aquamedic one I have is below par!

From all the tests this was for me the best one: https://www.ebay.co.uk/itm/UP-aqua-...ic-Diffuser-Reactor-check-valve-/401472727179

But you get the micro bubble cloud in your tank when the CO2 is on

From all the tests this was for me the best one: https://www.ebay.co.uk/itm/UP-aqua-...ic-Diffuser-Reactor-check-valve-/401472727179

But you get the micro bubble cloud in your tank when the CO2 is on

They're going to cost that kind of money though. If you look how much a big fluidused media reactor is its actually a lot more and the co2 reactor will have extra fittings.There used to be a great german company making and selling them on ebay, they did cost £80-100 a pop, maybe why they went bust and now all we have left is crappy reactors, I must have tried at least 20 different ones that I could find and they were all crap to be honest, should have purchased one of those german ones back in the day! Even the Aquamedic one I have is below par!

From all the tests this was for me the best one: https://www.ebay.co.uk/itm/UP-aqua-...ic-Diffuser-Reactor-check-valve-/401472727179

But you get the micro bubble cloud in your tank when the CO2 is on

What worked about the aqua medic?

Did you 'recycle the co2 with the bleed valve?

It didn't work!What worked about the aqua medic?

Haha, so what didn't work about it and what might make it work do you think.It didn't work!

What was the one sold on eBay like? I know you never tested it so I mean design and features.

I doubt it will ever work, maybe for a small tank, but not anything over 60l.so what didn't work about it and what might make it work do you think.

This was the German one:

zozo

Member

I used this one for a while the 12mm version.

https://www.ebay.com/itm/Aquarium-C...hash=item3ae5cabaeb:m:mYcunOOrJX1oI0qeJ9XXknQ

After finding out about that venturi story i immedialtely thought of ordering the 16mm version.. And fiddle me a venturi in the outlet connection side of that thing. I'm not sure how much flow you loose when changing to 16mm tube entirely with using the same pump and have a venturi in such a diffuser. That's my plan of testing one day with my next co2 project.

I've yet not seen any inline diffuser modle beter suited to DIY a venturi inside. How i'm going to fix that i yet do not know, but there are options and ideas.. Worst case scenario if i find nothing to make it from, i have to visite the local locksmith, he has the machinery to make me one.

https://www.ebay.com/itm/Aquarium-C...hash=item3ae5cabaeb:m:mYcunOOrJX1oI0qeJ9XXknQ

After finding out about that venturi story i immedialtely thought of ordering the 16mm version.. And fiddle me a venturi in the outlet connection side of that thing. I'm not sure how much flow you loose when changing to 16mm tube entirely with using the same pump and have a venturi in such a diffuser. That's my plan of testing one day with my next co2 project.

I've yet not seen any inline diffuser modle beter suited to DIY a venturi inside. How i'm going to fix that i yet do not know, but there are options and ideas.. Worst case scenario if i find nothing to make it from, i have to visite the local locksmith, he has the machinery to make me one.

AverageWhiteBloke

Member

That was the one I'm getting next zozo and going to feed it into the inlet of the canister. The beauty of it is you can get replacement generic 20mm ceramic discs in packs of 8 for a couple of quid so you always have plenty of spares to swap out while the others are cleaning. Maybe the best route would be having the reactor smaller and inlet and outlet pipes better positioned combined with one of these so the bubbles are small fed in and the reactor has less work to do. Key is making the reactor not reduce flow and get best of both worlds? Problem is if the pump needs to push through anything you're going to get reduction. My guess would be something on inlet that fully diffuses before hitting the canister preventing build up or burping. Its going to get dirty more often and full of mulm so some taps so it can be effortlessly removed quite often for a rinse so it doesn't become a nuisance would be my ideal.

Other than that this is way over my head but you guys would be the best to come up with something if anyone going off your previous DIY stuff I've seen. Sorry I can't be much more help, just putting it out there the type of thing that would open my wallet. Could it be crowd funded if Andy has the man to put some effort into professionally building it to make it worth their while?

Other than that this is way over my head but you guys would be the best to come up with something if anyone going off your previous DIY stuff I've seen. Sorry I can't be much more help, just putting it out there the type of thing that would open my wallet. Could it be crowd funded if Andy has the man to put some effort into professionally building it to make it worth their while?

Zeus.

Fertz Meister

People seem hell bent on inline diffusers but they still leave bubbles so if the reactor was affordable and a success then it should be

The JBL inline atomiser and APS EF is Bubble free and affordable , just just doesnt fit for you

zozo

Member

Could be this is what is used in florestas submersas.

http://www.purevtech.com/phure-feed/

This manufacturer calls it a friendly non toxic chemical Ph control unit with the use of Co2.. It only needs a minimum of 40 gallons p/m..

But intersting is to see the installation type diagrams.

http://www.purevtech.com/phure-feed/

This manufacturer calls it a friendly non toxic chemical Ph control unit with the use of Co2.. It only needs a minimum of 40 gallons p/m..

But intersting is to see the installation type diagrams.

Haha, strange they say somewhere about minimum flow 1000lph.I doubt it will ever work, maybe for a small tank, but not anything over 60l.

This was the German one:

Is the German one intended to be used horizontally? I see it has a bypass on though.

My filter traps air easy as anything so I'd only want it on the return side.feed it into the inlet of the canister

How many people would join us though?just putting it out there the type of thing that would open my wallet.

I just need a design to give him, I know many have tried DIY but it costs a lot by the time you add in fittings that you can take apart to clean etc so you may as well buy a quality built one. It's in the preliminary stages and if it works he will make them.Andy has the man to put some effort into professionally building it

The fittings on the APS are at an angle which makes things tricky in the space I have, if I can have a unit that enters through the top at 90 degrees that works well for my filter then exits the bottom at 90 degrees i can loop it back up for the inline heater. I also plan to use some rigid pipe.The JBL inline atomiser and APS EF is Bubble free and affordable , just just doesnt fit for you

Maybe if something could be made to diffuse the co2 in an easily replaceable fitting on the way in (in the way an inline atomizer does) this would be better than injecting direct into the cylinder of the reactor?

Zeus.

Fertz Meister

If the fittings on the APS EF are at bad angles, I would of thought other suitable fittings could be found that fit on the web that suit your plumbing/space

Sent from my Moto G (4) using Tapatalk

Sent from my Moto G (4) using Tapatalk

I think I said to you before I looked at making the holes bigger and putting different fittings on but by the time I've messed around and spent out on something that might work I could either DIY a reactor or see about getting one made which does everything (i hope) and I could hard plumb if I wanted.If the fittings on the APS EF are at bad angles, I would of thought other suitable fittings could be found that fit on the web that suit your plumbing/space

Sent from my Moto G (4) using Tapatalk