DavidW

Member

My current sump was working well until I had a power cut and subsequently flooded lounge  my other half was less that impressed the first time it happened and I wont repeat the barrage I got the second time.

my other half was less that impressed the first time it happened and I wont repeat the barrage I got the second time.

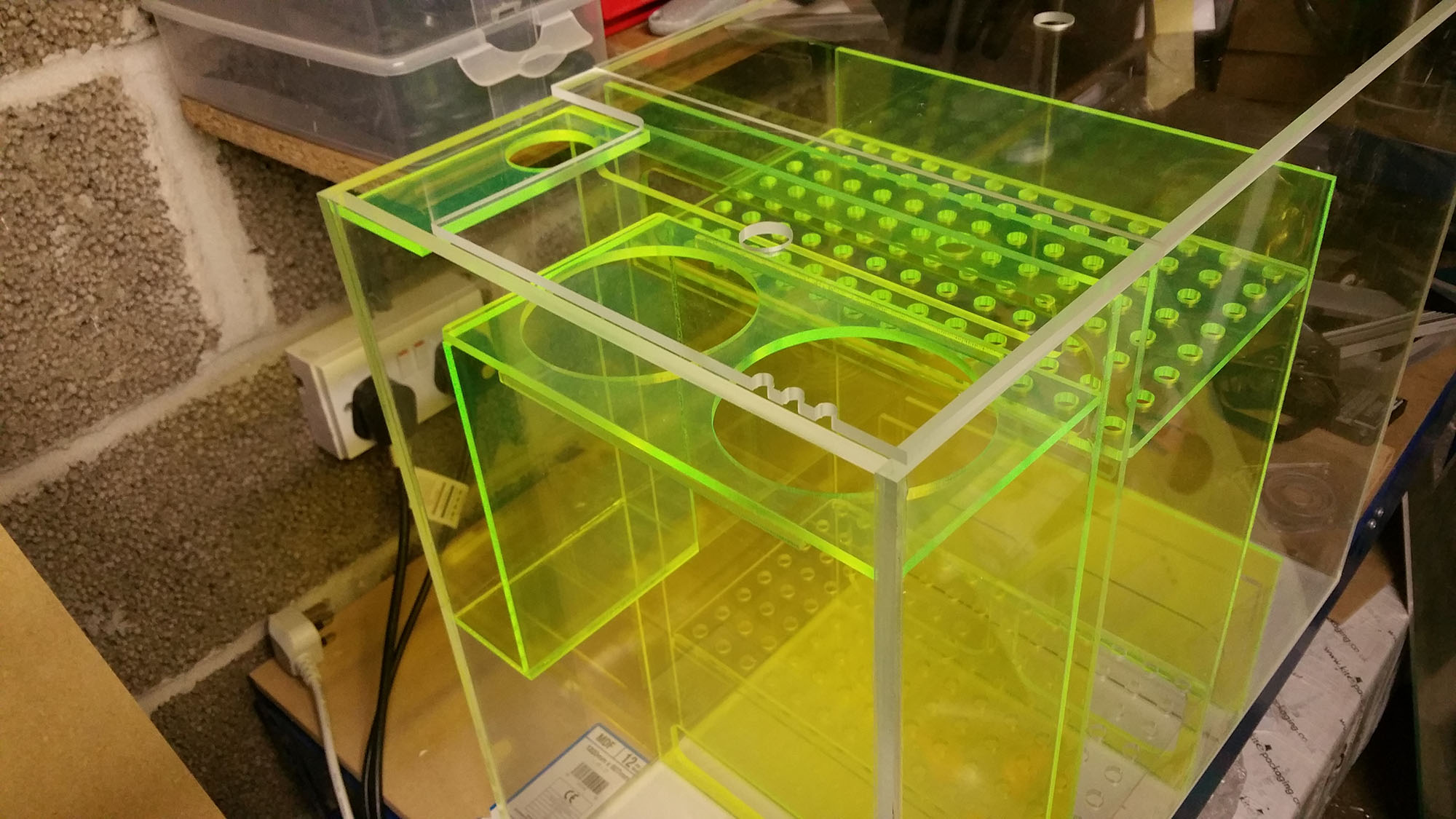

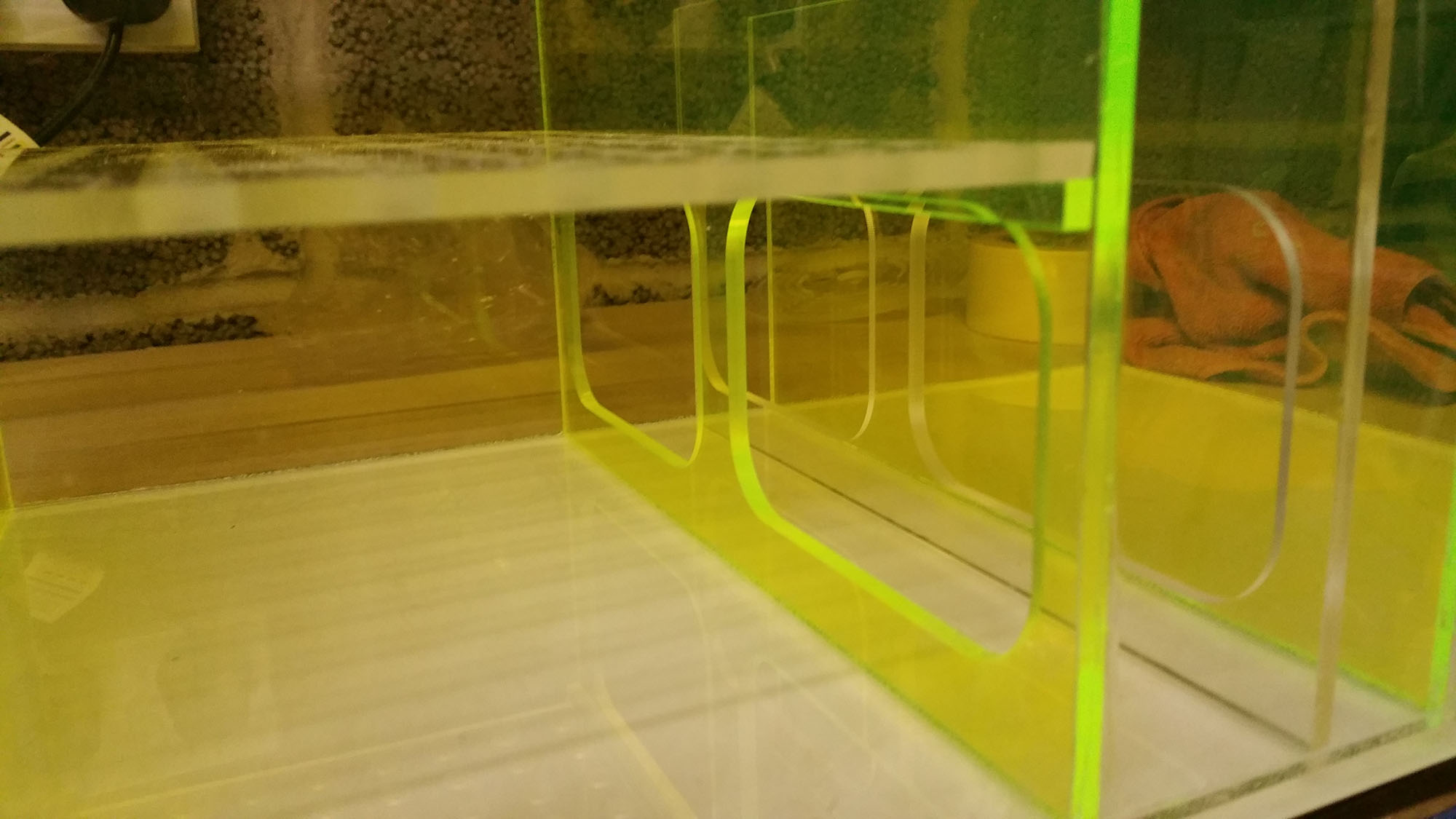

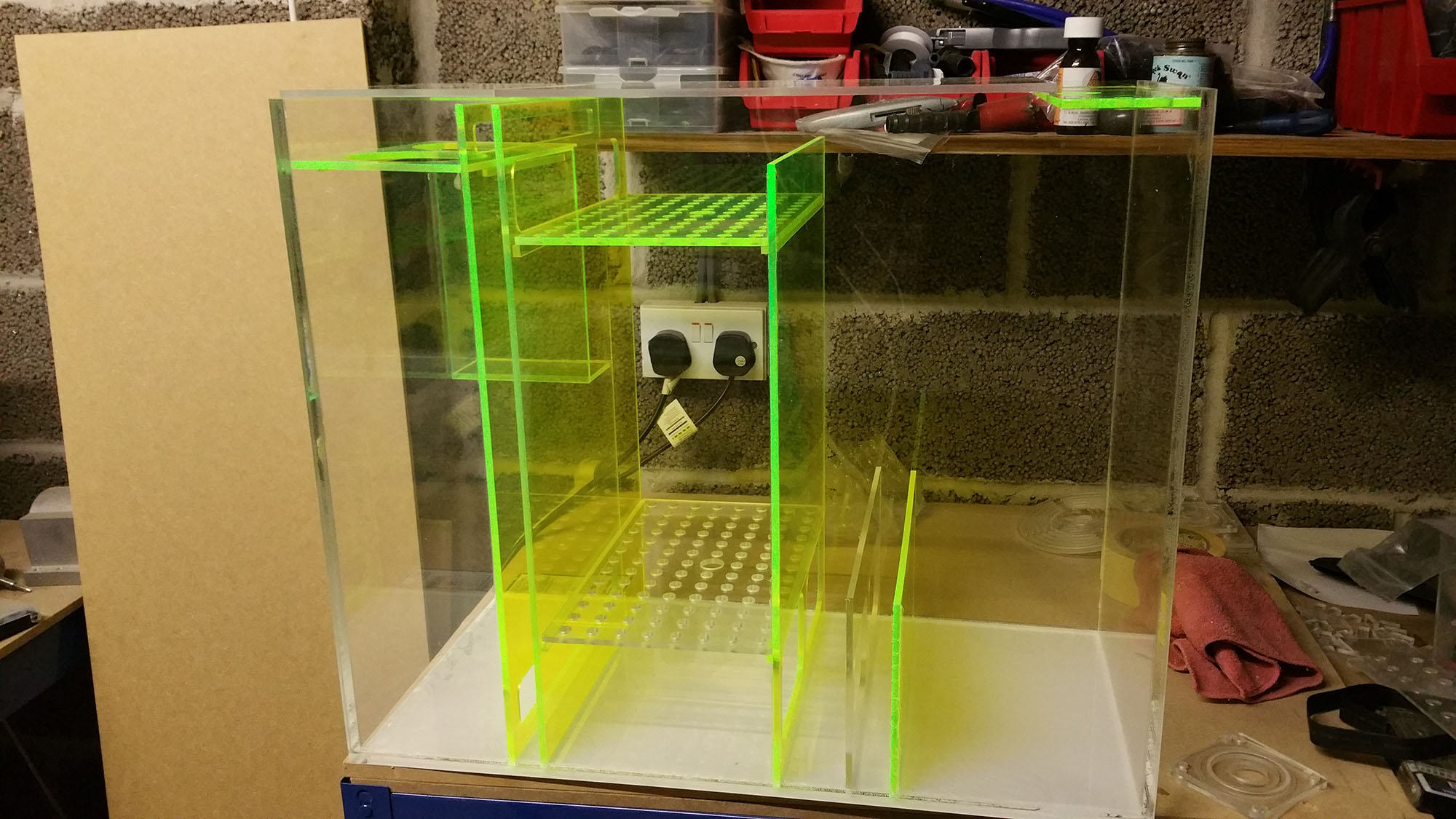

So I've been working on a new sump design for my tank that wont flood in a power cut. After putting some designs together I got in contact with a company that make acrylic sumps and they built it for me.

It arrives on Thursday here are some pictures

So I've been working on a new sump design for my tank that wont flood in a power cut. After putting some designs together I got in contact with a company that make acrylic sumps and they built it for me.

It arrives on Thursday here are some pictures