As some of you may know I am working on setting up this tank 3000 Liter High Tech Planted Tank I am considering different reactor designs and wanted to receive input on them and what would be the best for a 3000l tank.

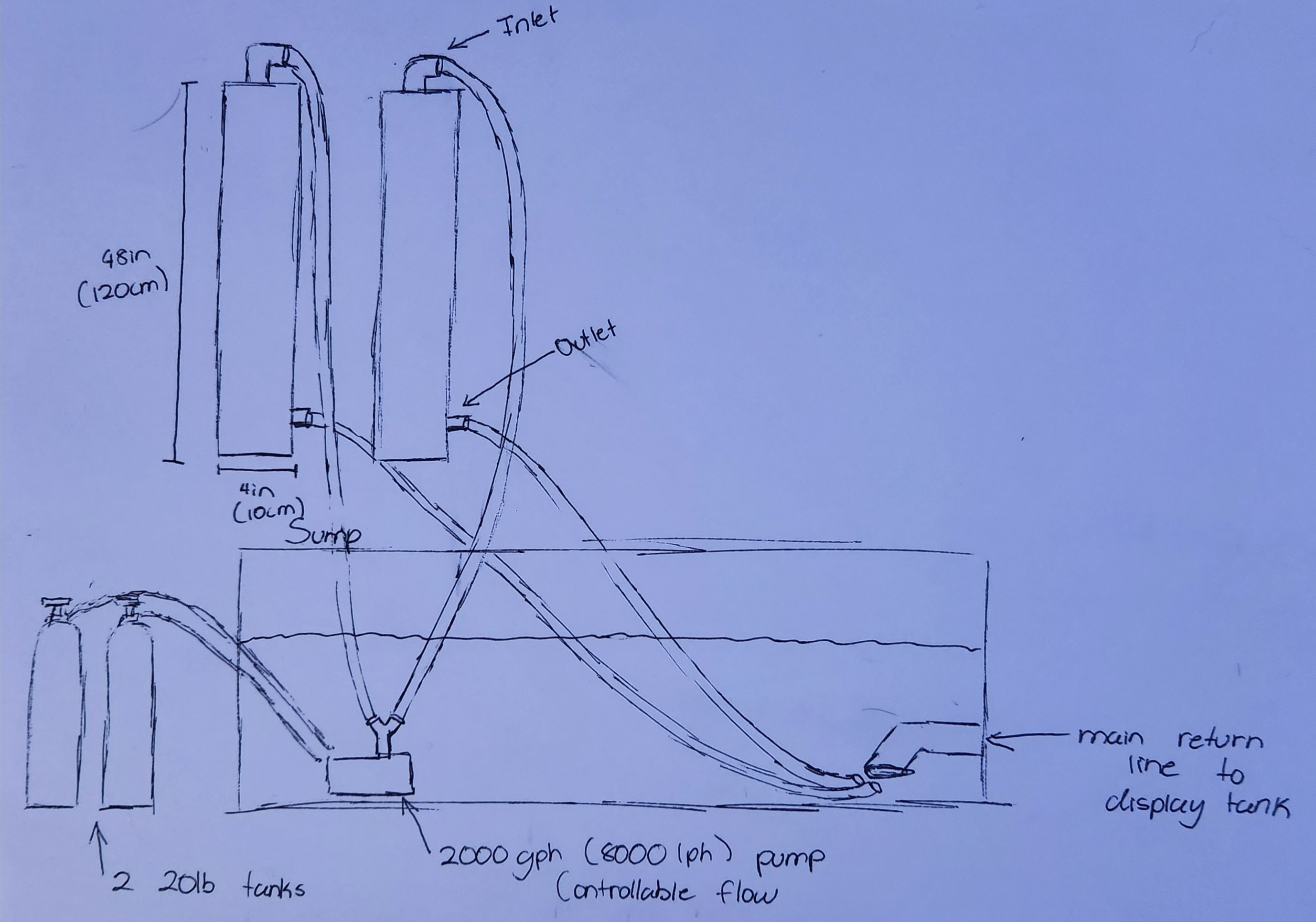

Here is one design, it is essentially a griggs style reactor from what I understand. I would have two 120cm reactors, 10 cm in width, with a 8000 lph pump splitting its flow into both reactors. The CO2 would be injected directly into the pump to crush the bubbles into microbubbles. The outlet of the reactors would go into the main return pump to the display tank. Thoughts on this design? Surely this is big enough for a 3000 liter tank with 800 liter sump.

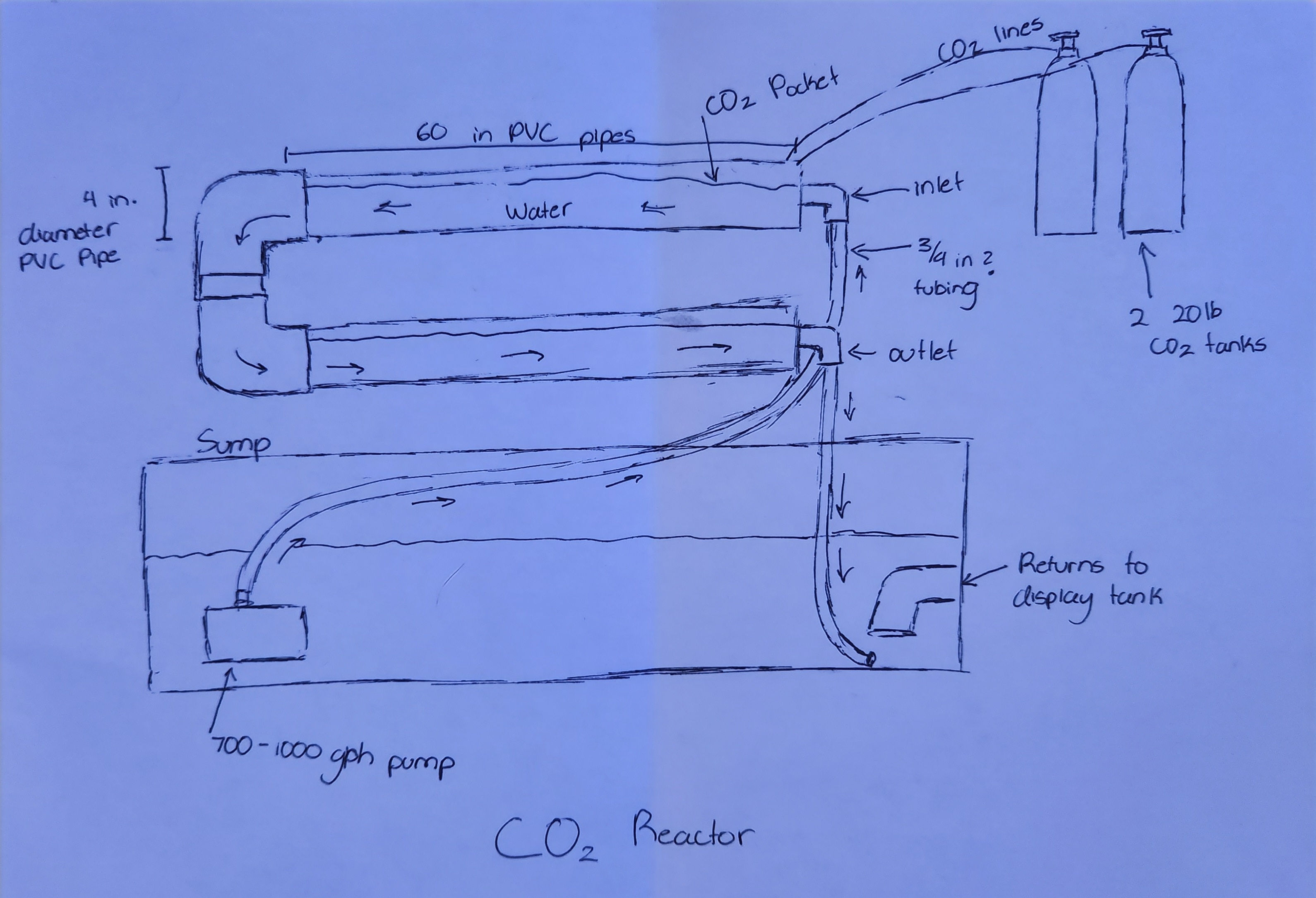

The second design is the Reactor

This is a horizontal reactor that works using a CO2 pocket with water flowing down absorbing the CO2. I really like the simplicity of this design but it has not been tested as much as the vertical style reactor like in the first design. I am still leaning towards this horizontal reactor but I wanted to make sure I am considering all the options.

Here is one design, it is essentially a griggs style reactor from what I understand. I would have two 120cm reactors, 10 cm in width, with a 8000 lph pump splitting its flow into both reactors. The CO2 would be injected directly into the pump to crush the bubbles into microbubbles. The outlet of the reactors would go into the main return pump to the display tank. Thoughts on this design? Surely this is big enough for a 3000 liter tank with 800 liter sump.

The second design is the Reactor

This is a horizontal reactor that works using a CO2 pocket with water flowing down absorbing the CO2. I really like the simplicity of this design but it has not been tested as much as the vertical style reactor like in the first design. I am still leaning towards this horizontal reactor but I wanted to make sure I am considering all the options.

Last edited by a moderator: